Enhancing Precision, Efficiency, and Innovation

Automotive

Driving Innovation in the Automotive Industry

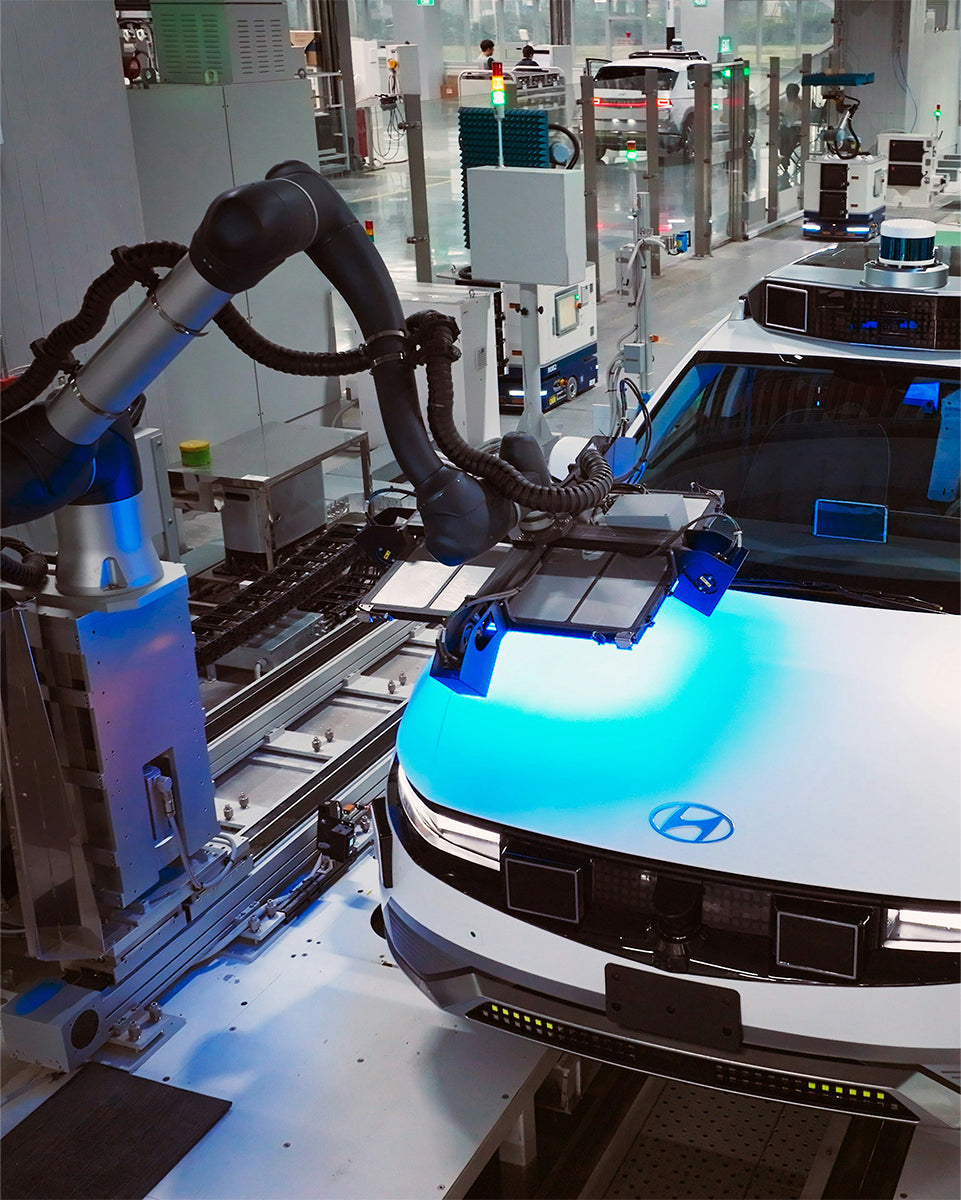

The automotive industry is rapidly evolving, driven by advancements in automation, safety, and efficiency. AL.Robot’s sensors are at the forefront of this transformation, providing essential feedback and control for a wide range of automotive applications. Our sensors ensure precision, reliability, and performance in vehicle production and operation.

Applications

- Assembly Line Automation

Our sensors are integral to the automation of assembly lines, ensuring precise alignment and fastening of components. This reduces errors and increases the speed of production. - Welding

Monitor and control welding forces to ensure strong, reliable welds without damaging components. - Fastening

Ensure the correct torque is applied during the fastening of bolts and screws, preventing over-tightening or under-tightening. - Quality Control and Testing

Utilize our sensors to perform rigorous quality control checks and testing procedures, ensuring that every vehicle meets the highest standards of quality and safety. - End-of-Line Testing

Verify the performance and safety of assembled vehicles with precise force and torque measurements. - Component Testing

Test individual components for durability and performance, ensuring they meet specifications before assembly.

- Material Handling and Robotics

Enhance the efficiency of material handling systems and robotic arms in automotive manufacturing. - Robotic Arms

Equip robotic arms with our sensors to improve the precision and reliability of tasks such as painting, assembly, and welding. - Material Handling

Optimize the movement and placement of heavy materials with accurate force and torque feedback. - Vehicle Dynamics and Performance Testing

Our sensors are used in the testing of vehicle dynamics and performance, providing

accurate measurements that are critical for development and improvement. - Suspension Testing

Measure forces and torques in vehicle

suspension systems to optimize ride quality and handling. - Engine and Transmission Testing

Monitor torque and force in engines and transmissions to enhance performance and reliability.

Key Benefits

Enhanced Precision

Achieve high accuracy in manufacturing processes, ensuring consistent quality and performance.

Improved Safety

Monitor and control force and torque to prevent damage and enhance safety in automotive applications.

Increased Efficiency

Optimize production lines and robotic systems for maximum efficiency and reduced downtime.

Trends and Innovations

- Electric Vehicles (EVs)

Crucial for manufacturing and testing EV components. - Autonomous Vehicles

Support the development and testing of autonomous systems. - Lightweight Materials

Assist in integrating and testing lightweight materials for better fuel efficiency.

Industrial Automation

Industrial Automation

Maximizing Efficiency and Precision in Industrial Automation

Industrial automation is the backbone of modern manufacturing. AL.Robot’s sensors are essential for enhancing the precision and reliability of automated systems, providing critical feedback that ensures smooth operation and high productivity in various industrial applications.

Applications

- Robotic Assembly and Machining

Equip robotic arms and CNC machines with our sensors to enhance precision and reliability in assembly and machining tasks. - Precision Machining

Monitor cutting forces to ensure high-quality finishes and prevent tool breakage. - Automated Assembly

Control the force applied during assembly operations to ensure proper fitting and alignment. - Material Handling and Packaging

Improve the efficiency and

accuracy of material handling and packaging systems with precise force and torque feedback. - Conveyor Systems

Optimize the movement of materials on conveyor belts, reducing jams and improving flow. - Packaging Automation

Ensure consistent force application during packaging processes, preventing damage to products.

- Quality Control and Inspection

Utilize our sensors for automated quality control and inspection systems to detect defects and ensure product consistency. - Automated Inspection

Perform detailed inspections with robotic systems equipped with our sensors to detect flaws and ensure quality. - Force Measurement

Use precise force measurements to verify product integrity and performance. - Predictive Maintenance

Implement predictive maintenance strategies using data from our sensors to identify potential issues before they cause downtime. - Condition Monitoring

Monitor the condition of machinery in real-time to detect signs of wear and prevent failures. - Maintenance Scheduling

Use sensor data to plan maintenance activities, reducing unexpected downtime and extending equipment life.

Key Benefits

Increased Productivity

Optimize processes for higher throughput and reduced cycle times.

Enhanced Precision

Achieve high accuracy in tasks, reducing waste and improving product quality.

Improved Reliability

Monitor and control forces to prevent equipment damage and extend machinery lifespan.

Trends and Innovations

- Smart Manufacturing

Integrate with IoT and AI for smart manufacturing solutions. - Sustainable Manufacturing

Support practices that optimize resource usage and reduce waste. - Collaborative Automation

Enable safer and more efficient human-robot collaboration.

At AL.Robot, we are committed to driving innovation in robotics with our advanced sensor technology. Each type of robot benefits from our expertise in force and torque measurement, ensuring that they operate with the highest levels of accuracy, efficiency, and reliability. Explore each application to discover how AL.Robot sensors can enhance your robotic systems.