Who We Are

Welcome to AL.Robot, a leading innovator in the field of smart ventilation controllers and force/torque sensors for robotics and other industrial applications. Established in 2017, AL.Robot has quickly become a trusted name in the OEM ventilation industry, known for our high-quality, high-performance ventilation controllers designed to meet the high standard of residential life (in Korean market).

Addressing Air Pollution and Indoor Air Quality (IAQ)

• Growing concerns over air pollution and stricter regulations on indoor air quality in OECD countries.

• Increasing demand for enhanced IAQ, particularly in urbanized regions with dense populations.

• Mandatory Ventilation Requirements (Korea): Since 2020, all apartment buildings with 30 or more units are required to install ventilation systems.

• The global push toward mandatory zero-energy buildings is reshaping construction practices and ventilation system demands.

• Rising Demand for Smart Ventilation Solutions: The market is rapidly shifting toward AI- and IoT-enabled ventilation systems to optimize energy efficiency, comfort, and air quality.

Business Performance

- Partnership with HIMPEL: Supplying advanced control units to HIMPEL, Korea’s leading residential ventilation controller manufacturer.

- Integrated Electronics: Ventilation control units with fully embedded electronics, including BLDC motors, ensuring seamless operation and efficiency.

- Customized ODM Solutions: Delivering tailored solutions for residential and commercial high-rise building ventilation systems.

- Projected Sales Growth

- 2023: 100,000 units sold annually.

- 2024: Anticipating a 50% increase to 150,000 units annually.

- Accumulated volume of over 400,000 up to now

Smart Ventilation Controllers

Key Features

• Precision Air Volume Control: 10-stage static air volume control with ±3% accuracy ensures optimal ventilation performance.

• Quiet and Energy-Efficient BLDC Motor: Designed for low noise and low power consumption, ideal for 24-hour operation.

• Air Quality Monitoring: Continuously tracks and analyzes air quality metrics for real-time optimization.

• IoT-Enabled Connectivity: Integrated WiFi module allows seamless integration with smart home systems and remote operation.

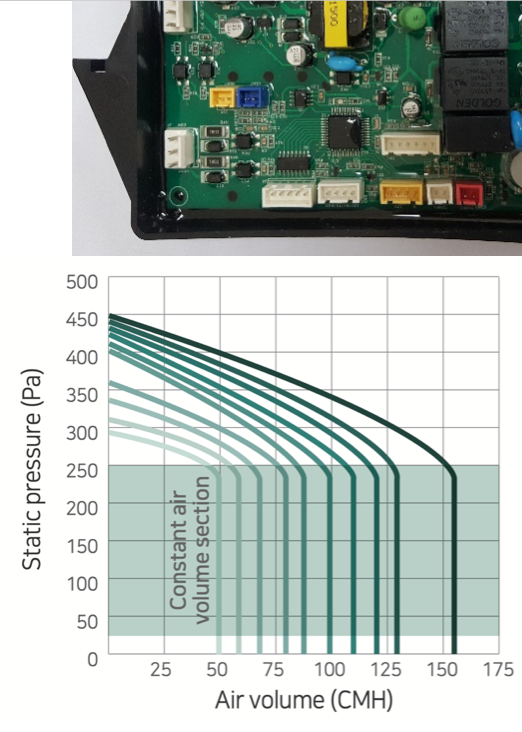

10-Step Constant Air Volume Control

• Unparalleled Precision: Maintains set air volume with an accuracy of ±3%, far exceeding competitors’ capabilities.

• Market Differentiation: While Panasonic offers only 3 levels of constant air volume control with 10% precision, this system provides industry-leading performance.

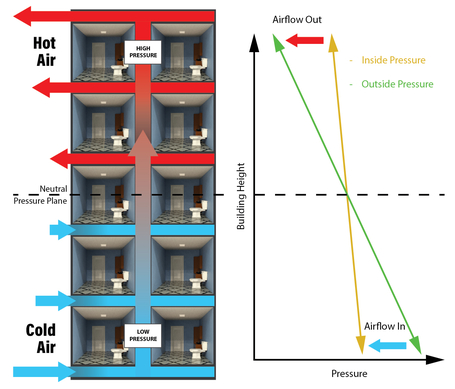

• Reliable Ventilation Performance: Delivers consistent airflow across both high-rise and low-rise environments, ensuring equal ventilation quality.

• Adaptive Operation: Maintains accurate performance even under challenging conditions, such as air pressure fluctuations, filter clogging, and temperature variations.

• Comprehensive Air Quality Management: Guarantees consistent indoor air quality in diverse environments, meeting the demands of modern ventilation systems.

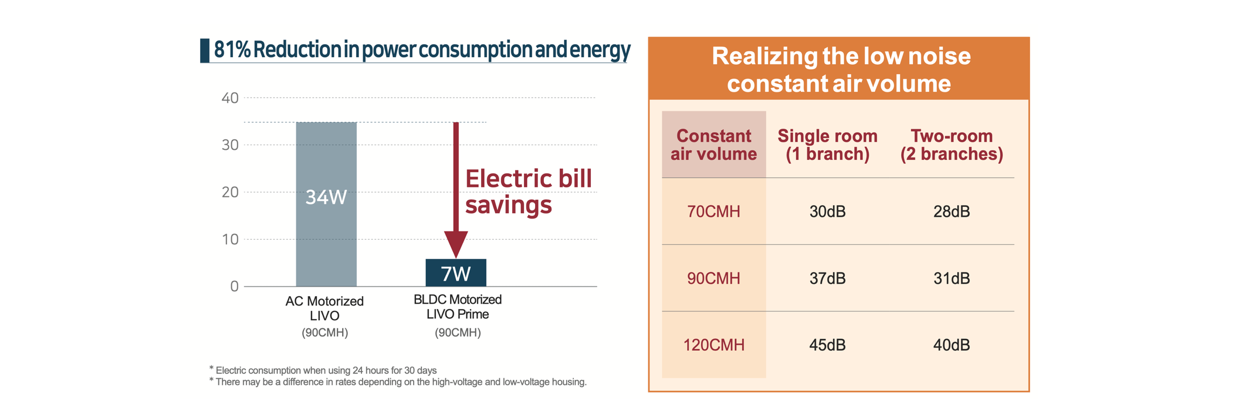

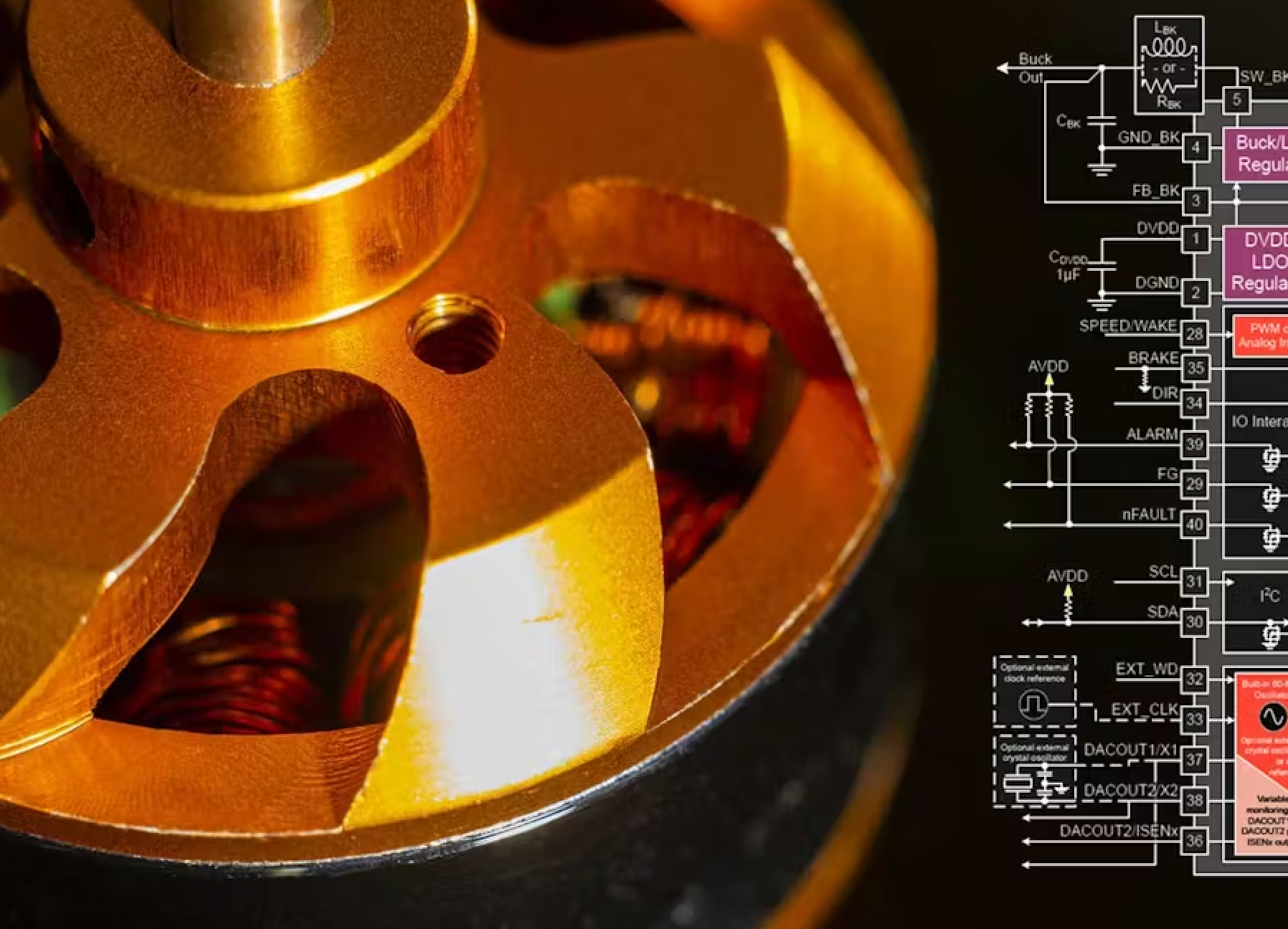

Low-Noise, High-Efficiency Control of BLDC Motors

• Energy-Efficient 24-Hour Operation: Designed for continuous ventilation with significant energy savings.

• Ultra-Quiet Performance: Minimized speed and torque ripple keeps noise levels below 30 dB.

• Noise Certification: Verified through authorized testing, ensuring compliance with stringent noise standards.

• Ideal for Residential and Commercial Spaces: Maintains a quiet indoor environment for enhanced comfort.

WHY AL.ROBOT?

Innovative Technology Leadership

• World’s First 10-Speed Airflow Control Technology: Delivers precise airflow adjustments for superior performance and energy efficiency.

• Advanced Quiet Motor Control: Ensures a comfortable and noise-free environment, ideal for residential and commercial applications.

• Energy-Efficient Design: Optimized to reduce power consumption, supporting sustainability goals and minimizing operating costs.

• Compact and Efficient Build: Easy to install, maintain, and operate, providing exceptional value for both manufacturers and end users.

Comprehensive OEM/ODM Expertise

• Tailored Solutions: Offers fully customized designs aligned with your product specifications, market demands, and brand identity.

• End-to-End Development Support: Facilitates seamless collaboration from concept to production, ensuring timely delivery and exceptional results.

Proven Track Record

• Robust Manufacturing Capabilities: Expertise in producing 150,000 control units annually, ensuring high-quality and cost-efficient mass production.

• Extensive Field Validation: Over 400,000 units installed, demonstrating reliability and consistent performance across diverse environments.

• Exceptional Quality Control: Advanced management systems ensure uniform quality standards are upheld even during large-scale production.

• Collaborations with Industry Leaders: Proven success in partnering with top domestic brands, delivering high-quality, competitive solutions tailored to market needs.

FAQs

What is the typical lead time for development?

Our standard development cycle is usually completed within six months of the project's start. This includes the initial testing, design, prototyping, and final approval stages.

Do you have a minimum order quantity (MOQ)?

Yes. Our low MOQ of 1,000 units ensures that both small-scale and large-scale customers can easily meet their requirements.

Can you accommodate varying production volumes?

Absolutely. Our adaptable manufacturing solutions support limited-batch and high-volume production, enabling us to meet a wide range of market demands.

How does your pricing structure work?

Pricing depends on the specific component or configuration required. We offer flexible options, such as:

- Control Board (Main Board): Priced per unit, based on complexity and components.

- Control Module (with BLDC Motor): Offers integrated functionality at a corresponding price point.

- Finished Product: A comprehensive package that includes all components and assembly, priced accordingly.

What is your development process from concept to mass production?

We follow a structured, five-step approach:

- Initial Testing and Evaluation: We examine existing solutions to identify gaps and opportunities for improvement.

- Requirement Analysis: We thoroughly assess your specific needs to ensure our solution aligns with your goals.

- Design and Prototype Development: Our team creates custom prototypes tailored to your requirements for initial review.

- Sample Testing: We rigorously test prototypes to validate their performance, functionality, and durability.

- Mass Production Approval: Once approved, we proceed with large-scale manufacturing and ensure consistent quality throughout the production run.